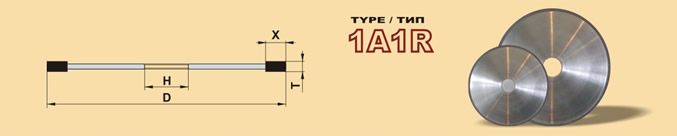

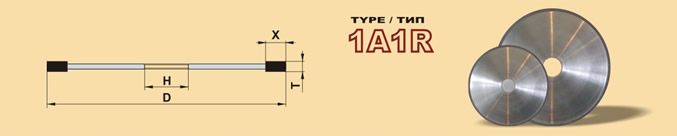

Diamond Cutting Wheel 1A1R_B

Diamond Cutting Wheel 1A1R_B

Cutting of hard alloys.

| D | T | X | H |

|---|---|---|---|

| 125 | 1.5 | 5 | 32 |

| 125 | 2.2 | 5 | 32 |

| 125 | 2.5 | 5 | 32 |

| 125 | 3.0 | 5 | 32 |

| 150 | 1.0 | 5 | 32 |

| 150 | 1.2 | 5 | 32 |

| 150 | 1.5 | 5 | 32 |

| 200 | 1.2 | 5 | 32 |

RECOMMENDATIONS ON APPLICATION

* For the wheels by the diameter up to 100 mm and body thickness up to 0.2 mm, diameter of clamping flanges should be equal to 0.8 external diameter of the wheel, for the rest wheels should be 0.5.

* When cutting ability of the wheel redused [so called "glazing"], it is necessary to open the diamond layer by making 2-3 cuts on any abrasive material.

Relative concentration of diamonds in diamond grinding wheels on bakelite bond are mentioned:

C2-50%; C3-75%; C4-100%, C5-125%; C6-150%.

| Order Example | 1A1R | 150x1.2x5x32 | D126 | B | C4 | ||||

| Main Symbols | |

|---|---|

| Relative Concentration | |

| Metal Bond | |

| Bakelite Bond | |

| Process with Cooling | |

| Symbols of sizes | |

|---|---|

| D, D1 | Diameter, mm |

| H | Tool bore, mm |

| T | Height, mm |

| X | Thickness of diamond layer, mm |

| W, U | Width of diamond layer, mm |

| V° | Angle |

| R | Radius, mm |

| L | Length, mm |

| H | Tapped hole, mm |

| E | Body Thickness, mm |

| S | Glass Thickness, mm |

| N | Quantity of segments, pcs |