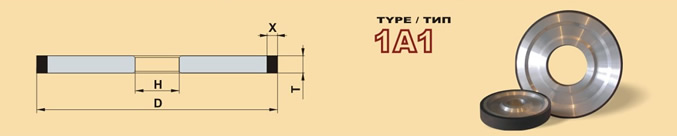

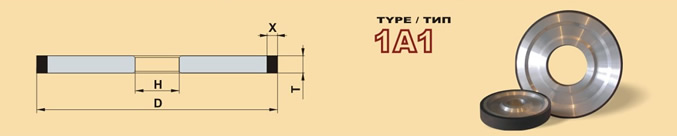

Diamond Grinding Wheel 1A1_B

Diamond Grinding Wheel 1A1_B

Cylindrical and surface grinding, sharpening and finishing of carbide tools, centerless grinding and machining of non-metallic materials.

| D | T | X | H | D | T | X | H | |

|---|---|---|---|---|---|---|---|---|

| 20 | 16 | 2 | 6 | 150 | 6 | 5 | 32 | |

| 25 | 16 | 3 | 6 | 150 | 8 | 3 | 32 | |

| 32 | 16 | 3 | 10 | 150 | 8 | 5 | 32 | |

| 40 | 10 | 3 | 16 | 150 | 10 | 3 | 32 | |

| 40 | 12 | 3 | 16 | 150 | 10 | 5 | 32 | |

| 40 | 16 | 3 | 16 | 150 | 15 | 3 | 32 | |

| 50 | 10 | 3 | 16 | 150 | 20 | 5 | 32 | |

| 50 | 16 | 3 | 16 | 200 | 6 | 3 | 76 | |

| 63 | 16 | 3 | 20 | 200 | 10 | 3 | 76 | |

| 80 | 10 | 3 | 20 | 200 | 10 | 5 | 76 | |

| 80 | 10 | 5 | 20 | 200 | 15 | 3 | 76 | |

| 100 | 8 | 3 | 20 | 200 | 15 | 5 | 76 | |

| 100 | 10 | 3 | 20 | 200 | 20 | 5 | 76 | |

| 100 | 10 | 5 | 20 | 200 | 40 | 5 | 76 | |

| 100 | 20 | 3 | 20 | 250 | 10 | 5 | 76 | |

| 100 | 20 | 5 | 20 | 250 | 15 | 5 | 76 | |

| 125 | 3 | 3 | 32 | 250 | 40 | 5 | 76 | |

| 125 | 5 | 3 | 32 | 300 | 15 | 3 | 76 | |

| 125 | 6 | 3 | 32 | 300 | 18 | 5 | 76 | |

| 125 | 10 | 3 | 32 | 300 | 20 | 3 | 76 | |

| 125 | 10 | 5 | 32 | 300 | 40 | 5 | 76 | |

| 125 | 15 | 5 | 32 | 350 | 20 | 5 | 127 | |

| 125 | 20 | 3 | 32 | 400 | 16 | 6 | 127 | |

| 125 | 20 | 5 | 32 | 400 | 20 | 6 | 127 | |

| 150 | 6 | 3 | 32 | 400 | 25 | 6 | 127 |

* Wheels of other geometrical parameters can be produced on request.

Relative concentration of diamonds in diamond grinding wheels on bakelite bond are mentioned:

C2-50%; C3-75%; C4-100%, C5-125%; C6-150%.

| Order Example | 1A1 | 200x20x5x76 | D91 | B | C4 | ||||

| Main Symbols | |

|---|---|

| Relative Concentration | |

| Metal Bond | |

| Bakelite Bond | |

| Process with Cooling | |

| Symbols of sizes | |

|---|---|

| D, D1 | Diameter, mm |

| H | Tool bore, mm |

| T | Height, mm |

| X | Thickness of diamond layer, mm |

| W, U | Width of diamond layer, mm |

| V° | Angle |

| R | Radius, mm |

| L | Length, mm |

| H | Tapped hole, mm |

| E | Body Thickness, mm |

| S | Glass Thickness, mm |

| N | Quantity of segments, pcs |